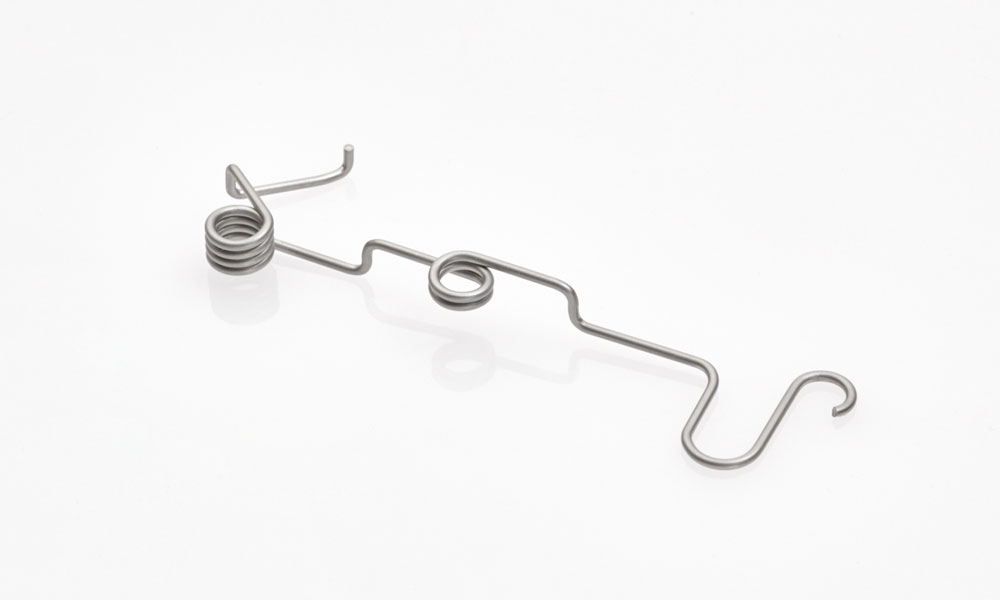

Torsion springs

Coil springs, which are used for transmitting torque or for storing torsion, are referred to as torsion springs. Since the load is always introduced at the ends of the spring via legs of varying length, they are also known as leg springs. Torsion and leg springs are engineered and designed in a standardised manner.

One of our specialities is the fully automatic production of torsion springs (leg springs and double-leg springs) with computer-aided, freely programmable and electronically controlled wire forming machines for single parts and large-scale production.

Integrated measuring and assembly technology guarantees efficient and reliable production. Shot-blast for heavy-duty use. Springs are developed and tested for use in fluctuating load test stands.

At Velleuer, all torsion springs are cold formed. Depending on the application, different materials are used in their production.

The most common basic types of torsion and leg springs used by Velleuer have either one or two winding bodies arranged symmetrically to each other. The legs can be shaped differently, depending on the intended purpose.

The available installation space, the spring retainer, the torsion to be stored and the connection to the machine component to be rotated are the defining criteria when designing a leg spring.

Materials & Production Capabilities

-

Materials:

EN 10270-1 Patented cold drawn unalloyed spring steel wire

EN 10270-2 Oil hardened and tempered spring steel wire

EN 10270-3 Stainless spring steel wire

Special materials after individual consultation -

Wire diameter d:

Min.: approx. 0.4 mm

Max.: approx. 4 mm - Leg lengths and leg shape:

Single- and double-leg springs

Custom spring ends

Customised versions and bespoke dimensions are possible after individual consultation.

Contact Us for Torsion Springs

Looking for a reliable partner for high-quality torsion and leg springs? We’d be happy to support you with expert advice and tailored solutions. Simply get in touch – we look forward to hearing from you!

Ernst W. Velleuer GmbH & Co. KG

Heidestraße 115

42549 Velbert

- Phone: +49 2051 290-0

- Fax: +49 2051 290-230

- Email: info@velleuer.de

- Contact Page: https://velleuer.de/en/contact/